- Steam or hot water boiler control

- Saves fuel

- Stand-alone trim control

- Air or fuel trim

- Variable-speed drive option

- Works with standard or Siemens gas trains

- User-friendly setup

- Applicable to new equipment or existing boilers as retrofit / upgrade

The Cleaver-Brooks Accu-Trim O2 Trim System is a stand-alone, PLC-based control system designed to maintain the proper fuel-to-air ratio of a boiler/burner. The system will automatically compensate for changes in temperature, barometric pressure, or fuel characteristics, as well as correcting for normal hysteresis. The system is intended for use with single-point positioning, or jackshaft-type, combustion controls; however, it may be customized for special applications such as parallel positioning or alternate fuel firing. A complete system includes oxygen and firing rate sensors, a control panel, which houses the PLC, and an actuator or VSD system, which trims either the fuel or airflow.

- Complete boiler control system

- Proven Allen Bradley PLC platform

- Advanced multi-touch screen

- Intuitive interface

- New or retrofit boiler applications

- Steam or hot water

- Built-in lead lag

- Keeps your boiler running at peak performance year around, saving energy

- High resolution advanced multi-touch interface

- Built in two-boiler lead lag

- Precision fuel-to-air ratio control

- O2 trim

- NOx trim

- Variable-speed drive control

- Fan motor vibration monitoring

- Draft control

- Flexibility and custom applications

- Standard Honeywell CB780E integrated burner management system or Fireye (CB120E) as an option

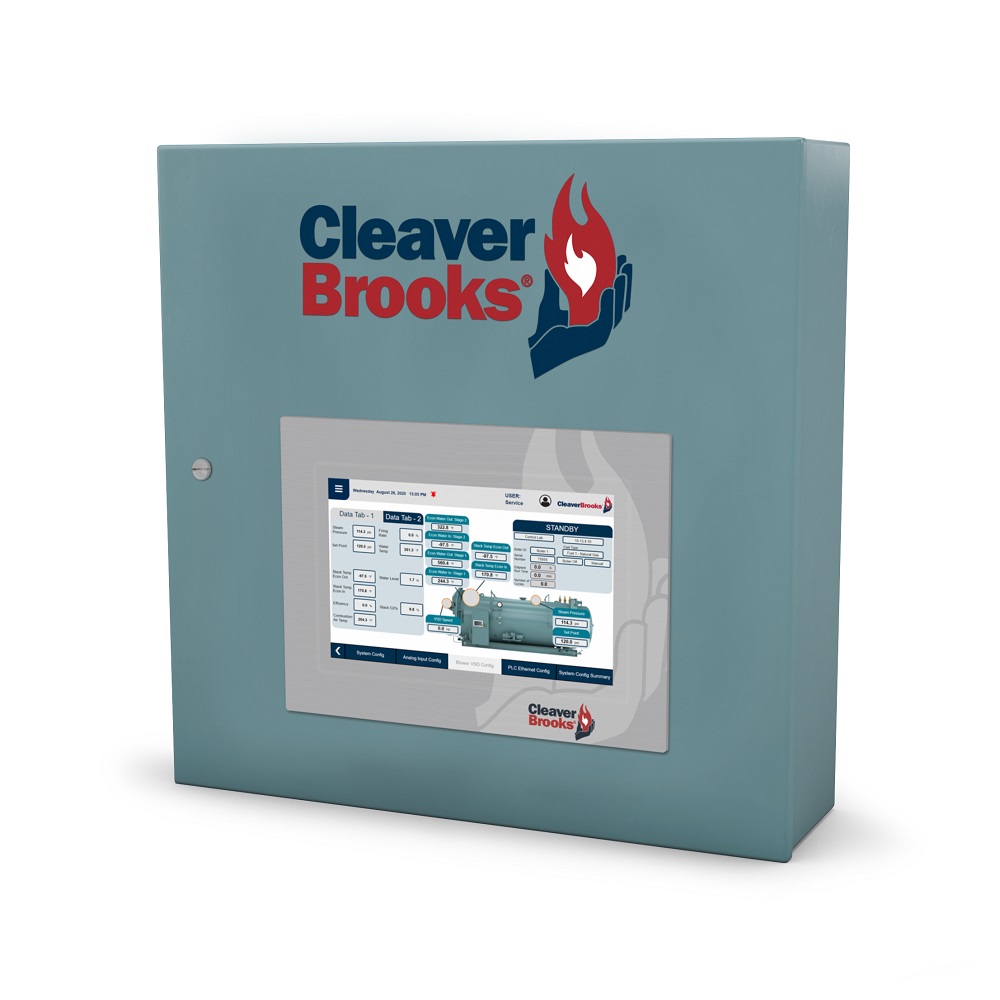

Hawk boiler controls offer the most advanced features on the market and are configurable to meet the demands of almost any steam or hot water system. Key features and system-based control help ensure your boilers are operating at the highest efficiency. awk Boiler controls are available in two platforms – Hawk 1000 and Hawk 4000. Hawk 1000 is designed to meet the needs of most steam and hot water systems. This complete controls package is ideal for those systems requiring precise fuel to air ratio control, O2 trim, variable-speed combustion air fan. Also includes built-in two-boiler lead lag functionality. Combustion and burner management controls are integrated into the same console but maintained as separate devices to meet NFPA85 and other safety codes and requirements. The user-friendly, touch-screen interface alleviates memorizing cumbersome and complicated menu systems.

The Hawk 1000 has an intuitive user interface and is available with a 6” Color touchscreen. Hawk 4000 has all of the features of the 1000 but adds economizer control, draft control, boiler fan motor vibration monitoring and other advanced boiler control functionality housed in one integrated package. Custom programming and advanced communications features available in the HAWK 4000 make it ready for any future upgrades needed for your boiler system. Hawk 4000 boiler controls are available with the most advanced interface on the market. The large high resolution multi-touch interface is available with a standard 12” or optional 15” screen making the Hawk system the easiest and most modern boiler control on the market.

- Lower fuel cost

- Cutting edge combustion control with options for fuel-to-air parallel positioning control, full metering control, or single point positioning control

- User friendly interface and environment

- Fully programmed and tested at the factory for easy commissioning using the local HMI touch screen

- The Hawk 4500 is a complete burner boiler control system designed to North American standards (UL NFPA 85 or CSA B149.3) for institutional and industrial markets

- User friendly interface and environment

- Keeps your boiler running at peak performance year around, thus saving energy

- New or retrofit boiler applications

- Single-point precision parallel positioning or full metered control

- O2 trim options

- Variable-speed drive option

- Flexible and custom applications

- Fireye integrated burner management system

- Draft control

- Economizer monitoring and control

- Other boiler control requirements

The Hawk 4500 is a complete boiler control system for new or retrofit industrial watertube boilers and burners. Advanced features include economizer control, draft control, and full metering options. The complete control package is ideal for those systems requiring single point, parallel positioning or fully metered controls for industrial watertube boilers. Options are available for O2 trim, variable-speed drive, economizer control, and other boiler control requirements housed in one integrated package. Combustion and burner management controls are integrated into the same console but maintained as separate devices designed to comply with NFPA85, CSA B149.3 North American Standard code requirements. The user-friendly, touch-screen interface alleviates memorizing cumbersome and complicated menu systems. The Hawk 4500’s advanced communication functions make it one of the most flexible control systems available in today’s boiler control marketplace.

- Lower fuel cost

- Parallel positioning, full metering or single poin

- Cutting edge combustion control logic in a user-friendly environment

- Full configured including preset combustion parameters for easy commissioning from HMI

- 10″ color touch-screen interface, PLC based

- Fireye (CB120E) based integrated burner management system.

- Allen-Bradley Panelview Plus 10” color touch screen HMI for setup, monitoring and data acquisition using latest display ergonomics.

- Various screen size option with capabilities to mimic PLC screens to PC environment. Pre-configured and fully tested at our facility before shipment.

- Commissioning tuning done from the HMI including our new fully metered fast setup procedure. ISA (International Society for Automation) standard used for symbol labeling of the HMI and documents.

- Nema 12 Industrial grade enclosure (Nema 4 or 4X in option) wall-mounted or free-standing. NFPA 85 – 2011 or CSA B149.3 compliance

- Professionally assembled and pre-wired internal components compliant with UL/CSA Standards for industrial control enclosure.

- Supplied with a complete set of documents meeting the industry standards.

- After sale support by factory control system engineer and/or Field service technician.

- Training program available.

- Economizer monitoring and control

The Hawk 6000 package includes the same features and flexibility of the Hawk 5000, but engineered for total integration with the Cleaver-Brooks Configurable Watertube (CBCW) requiring single point positioning, parallel positioning or fully metered controls. This complete boiler control system meets institutional and industrial market specifications for North America standards. A simple and user-friendly interface provides access to the latest combustion control logics; benefiting from years of proven engineering experience developed for the petrochemical and utility markets. All commissioning can be performed through the HMI. Inputs and outputs have been pre-characterized to obtain linear response at all boiler loads and avoid tedious f(x) entries. The result is unsurpassed performance when coupled with a C-B industrial burner system. All Hawk 6000 systems include Ethernet communication, first out and alarm history, local or remote steam demand and much more.

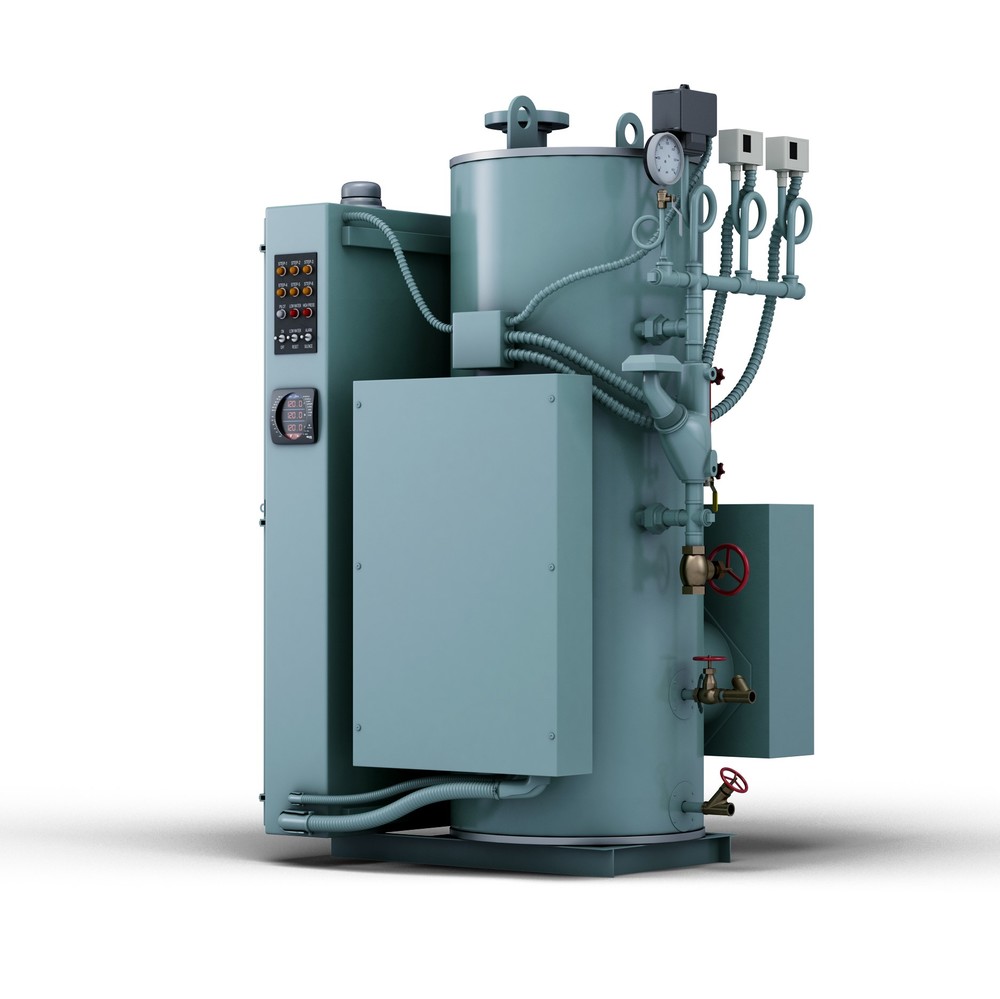

The Cleaver-Brooks Model S is an immersion-element steam electric boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Available in vessel sizes ranging from 12″ to 48″ diameter with an output spanning 12 kW to 2,250 kW. A typical Model S boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric vertical steam boiler

- 12 to 2250 KW – up to 7,875 lb/hr

- Up to 600V

- 15, 150, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation

The Cleaver-Brooks Model WB is an immersion-element hot water boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Vessel sizes range from 12″ to 42″ diameter with an output spanning 12 kW to 3,360 kW. A typical Model WB boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric hot water boiler

- 12 to 3360 kW, up to 11.5 million Btu/hr

- Up to 600V

- 160, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation with virtually no noise emissions

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation