- Steam or hot water applications

- Single-stage condensing economizer

- Saves energy by capturing waste heat

- Preheats any cool liquid stream

- Boilers up to 2,500 HP

- Accommodates all boiler design pressures

- Single-circuit heat transfer cold makeup, ice-cold process water preheater (Less than ~120°F)

- Tube core assemblies are individually removable and made from 316 stainless steel tube with aluminum fins (Al-Fuse)

- 316 stainless steel exhaust gas bypass, interior shell, condensate drain, and transition connections

- Hinged access door for complete internal inspection

- TP 316L pressure vessel side tube heat transfer section

- Condenses on natural gas only

The C1X Condensing Economizer saves fuel by preheating virtually any cool liquid stream (makeup water, wash water, hot water preheating, process, etc.) by capturing waste heat from a boiler stack. The unit has individual fin tubes compression-fitted to the liquid manifold for ease of tube replacement requiring no welding. It increases the amount of heat recovered by capturing both sensible and latent heat. The internal gas bypass can be used to maintain water temperature when too much heat is available.

- Steam applications

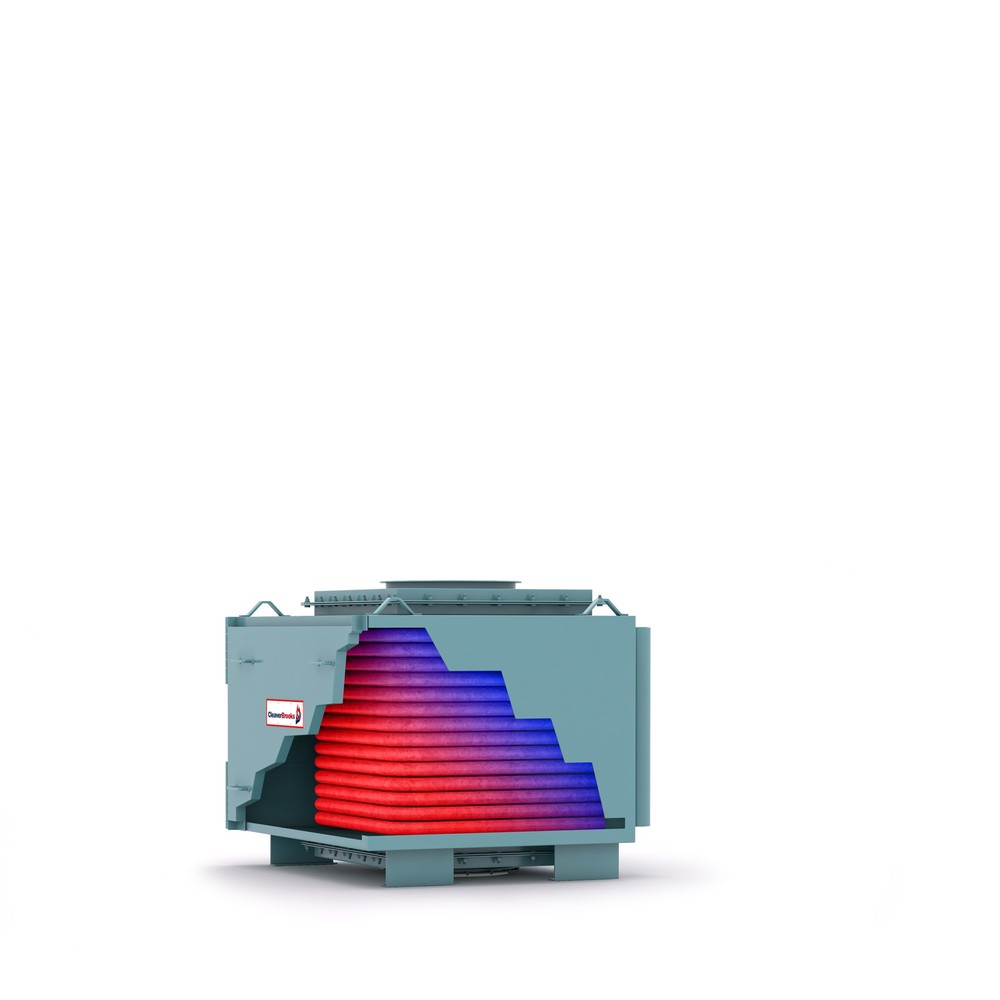

- Two-stage condensing economizer

- Ideal for larger boilers

- Boilers up to 2,500 HP

- Accommodates all boiler design pressures

- Separate upper and lower coils – allows heating of two completely separate liquid streams without cross-contamination

- Tube core assemblies are individually removable and made from 316 stainless steel tube with aluminum fins (Al-Fuse)

- 316 stainless steel exhaust gas bypass, interior shell, condensate drain, and transition connections

- Hinged, stainless steel access doors

- All gas side surfaces are 316 stainless steel to eliminate corrosion

- Condenses on natural gas only

The C2X two-stage Condensing Economizer is a condensing economizer that captures heat through both a traditional stack economizer section and a condensing section. Can be utilized on boilers up to 2,500 HP. The non-condensing section of the economizer recovers energy by preheating the boiler feedwater. The condensing section preheats virtually any cool liquid stream (makeup water, wash water, hot water preheating, etc.), and the control system maximizes condensing when firing natural gas, then automatically switches to a near-condensing mode when firing #2 oil (if applicable). The condensing section allows the latent heat to be reclaimed from the flue gasses, achieving the highest possible efficiencies. The upper coil, lower coil, modulating valves, control system, and other system components are sized as a system to deliver the maximum possible cost savings.

- Up to 94% efficiency

- Two-stage condensing economizer

- Available for 100 to 800 HP boilers

- Firetube or flextube steam boiler applications

- Can preheat large volumes of process hot water

New technology exclusive to Cleaver-Brooks enables the C2X-HE to be the first two-stage condensing economizer in the industry to achieve up to 94% efficiency. It is smaller and lighter than current two-stage economizer models and is ideal for high-percentage makeup water or process hot water applications. The C2X-HE is the first two-stage condensing economizer to achieve up to 94% efficiency. Every 1% increase in efficiency correlates to a 1% reduction in emissions, so the C2X-HE helps meet both efficiency and emissions reduction goals.

- Steam or hot water applications

- Non-condensing economizer

- Preheats boiler feedwater

- Boilers up to 2,500 HP

- Accommodates all boiler design pressures

- Rectangular model

- Individually removable, finned tubes

- No pressure vessel welds within the shell

- Hinged, stainless steel access doors

- Stainless steel, internal exhaust gas bypass

The CRE Rectangular Economizer can be utilized up to 2,500 HP for capturing the waste heat and preheating boiler feedwater, makeup water heating, hot water boilers, and potable and process water applications. The unit has individual fin tubes compression-fitted to the liquid manifold for ease of tube replacement requiring no welding. The large number of standard models provide combinations that work in applications with space constraints while still achieving maximum heat recovery.

- Steam or hot water applications

- Saves fuel by preheating feedwater

- Boilers up to 250 HP

- Accommodates all boiler design pressures

- Accommodates heavy oil fuel

- Cylindrical model

- Compact and lightweight

- High energy recovery

- Hinged, stainless steel access doors

- Stainless steel, internal exhaust gas bypass

The CCE Cylindrical Economizer can be utilized on boilers up to 250 HP for boiler feedwater, makeup water heating, hot water boilers, and potable and process water application. Flexibility allows specific engineering requirements to be met, such as fin spacing for fouling conditions and low gas pressure drops. The internal gas bypass can be used to temper the exiting gas for stack corrosion control or to maintain water temperature when too much heat is available. The large number of standard models provide height and diameter combinations that work in applications with space constraints, while still achieving maximum heat recovery.

- Small footprint

- 316 stainless steel tubing

- 316 stainless casing construction for the external economizer model

- Up to 87% boiler efficiency

- Virtually maintenance free

The ClearFire Economizer (ECF) is ideally suited for applications utilizing the horizontal CFH firetube or the vertical tubeless CBT model. Efficiency gains can reach 3-5% depending on the feedwater return temperature. The Integral economizer is available for high pressure steam CFH applications or the external economizer can be used in low pressure CFH or CBT needs.