- Simplex or Duplex Design

- 12–135-gallon capacity

- Stainless Steel Vertical

- Flange Mounted Centrifugal Pumps

- Allows for occasional pumping of small solids without clogging

- 250°F mechanical seals, equipped with a seal cavity bleed line to prevent seal failure

- Simplex & duplex units

- 304 stainless steel receiver tanks

- Standard unit factory wired for 1/60/115/208-230v or 3/60/208-230/460v operation

- Optional control panel available

- Pump is stainless steel vertical flange mounted centrifugal design

- Standard tank sizes are: 12-135 gallon (larger and custom sizes are also available)

Condensate Return System, built with dependable, long-lasting components. Cleaver-Brooks stainless-steel condensate return units come standard with a 10-year warranty against failure due to corrosion. Floor mounted units are rated for 200°F condensate and up to 210°F at certain operating points. Standard compact and custom systems are available with numerous options. Condensate Return System helps to improve energy efficiency, reduce chemical costs, reduce make-up water costs, reduce sewer system disposal costs, and meet environmental regulations by returning condensate back to the system.

- Ideal for packaged skid solutions or standalone installations

- Ease of maintenance

- Efficient operation

- Anti-scaling circulator

- Inlet strainers

- 3-way electro-hydraulic modulating valve

- Full color touchscreen controller with PID set point control

- Control system includes alarm contacts, data-logging and Modbus communication

- Ideal for packaged skid solutions or standalone installations

- Ease of maintenance

- Efficient operation

- Anti-scaling circulator

- Inlet strainers

- 3-way electro-hydraulic modulating valve

- Full color touchscreen controller with PID set point control

- Control system includes alarm contacts, data-logging and Modbus communication

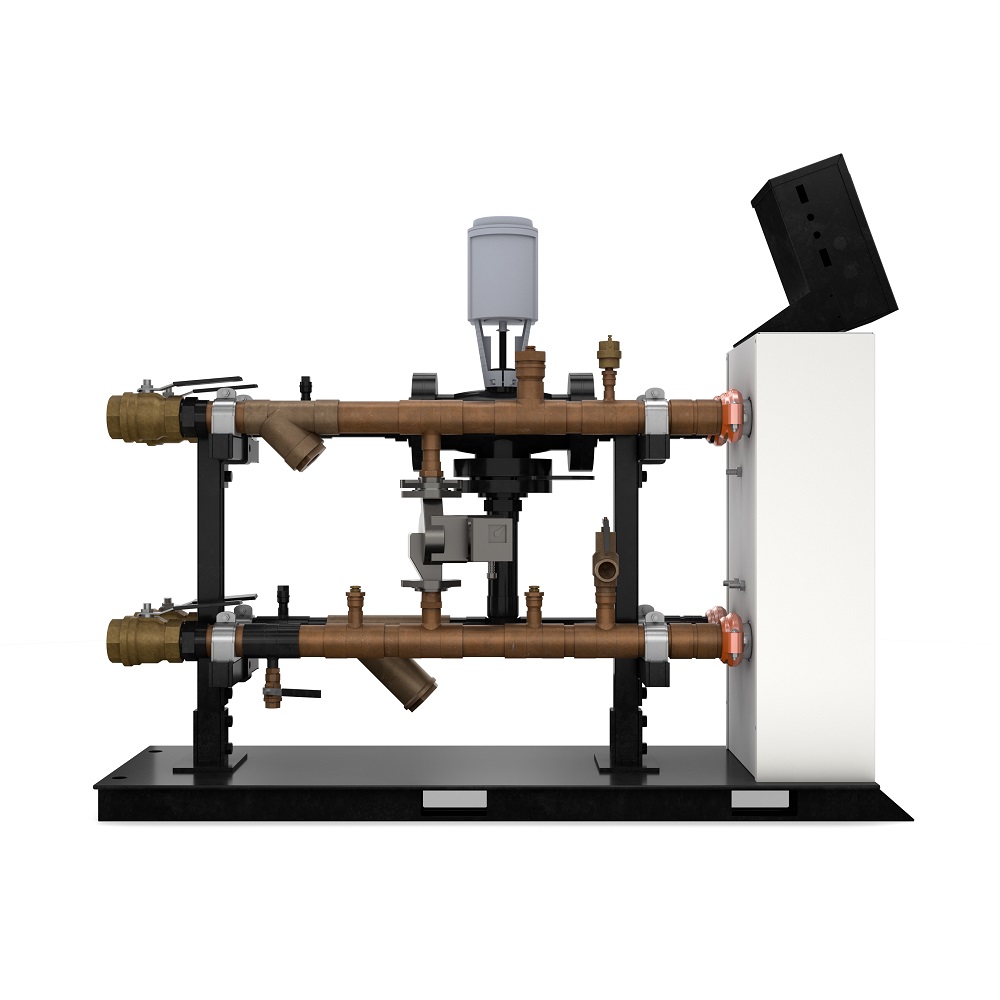

The HxO is a packaged water heater solution that provides optimal energy control between a hydronic boiler loop and a (domestic hot water) DHW or process water. Heat is extracted from the boiler loop through a very compact and efficient heat exchanger and is transferred to the cold domestic water supply. Each HxO model has been designed for an application with the specific flow and temperature ranges on the process and boiler sides. The intelligent PID control maintains process outlet temperature within +/- 2° F of set point. The HxO is designed to provide instantaneous Domestic hot water supply to your building without the need for additional fuel fired or electric heating equipment. By utilizing your new or existing hot water heating loop, the HxO will provide on-demand water for your system.

- For Steam and Hot Water applications

- Cools water for sampling

- Does not interrupt boiler operation

- Simple, easy-to-maintain design

- For any boiler size

- True counterflow cooling

- Compact design

- Stainless steel coil

- Removable shell

The sample cooler is a low-pressure-drop system for monitoring boiler water quality without shutting down the boiler system. Heavy-duty, all stainless-steel wetted parts. The design has baffling on the shell side to achieve high cooling-water flow, minimizing pressure drop, vibration, and scaling. A simple, compact design cools samples with minimum disturbance to system pressure.

- Standard or Maximum Noise Reduction Designs Available

- Noise Reduction Range: 24.4-48.4 dB

- Carbon Steel Design

- Two Absorption Chambers

- Horizontal and Vertical Drain Connection Standard

- Two Absorption Chambers

- Perforate plate backed with acoustical material for both high and low frequency noise attenuation

- Horizontal and vertical drain connections for installation flexibility

C-B Exhaust Silencers are single pass devices designed to give maximum attenuation of both low and high frequency noise for steam exhaustion to the atmosphere. Two models are offered – the SES-S and the SES-H, the latter a longer design for increased noise attenuation. The steam enters the inlet of the silencer where the flow is dispersed through the inlet diffuser tube into hundreds of small jet flows. This provides for a quiet flow into the silencer and the first stage silencing chamber. The diffuser also directs the flow toward the outer walls of the silencer body. The steam then repeats the process, contracting and expanding into the second stage chamber. Steam is quietly released to the atmosphere through the silencer outlet.