- System control for boiler systems

- Lead-lag for up to 8 boilers

- Reduce boiler cycling

- Color touch-screen interface, PLC-based

- Keeps your boiler running at peak performance year around, saving energy

- Lead-lag control of multiple boilers and other equipment

- Unique algorithms reduce boiler on-off cycling due to effective load management

- Incorporates lead-lag or unison modulation for steam or hot water boiler systems

- Auto rotation schedules

- Run time monitoring

- Isolation and primary pump control for hot water applications

- Built-in intelligence for system control

The C-B Master Panel is the system interface between each individual boiler’s control system and other boiler room equipment such as the ADAC and Hawk controls, as well interface for building automation systems. The Master Panel is the plant-load control for any application. It features an open-control platform that works with any boiler system and can be configured or custom programmed by Cleaver-Brooks to meet your needs.

- Hybrid hydronic boiler applications

- Condensing and non-condensing boiler plant

- System and boiler pump and valve control

- Domestic hot water control

- Draft damper start interlock

- Data logging

- Modbus communications to BMS

- Outdoor reset capability

The Hydronic System Control is a PLC based boiler sequencing and modulation control for hydronic heating applications. It works with condensing, non-condensing, and hybrid applications to deliver required building heat while saving on fuel. By controlling the condensing and non-condensing boilers using independent PID loop control, the HSC can optimize boiler operation based on the unique characteristics of each boiler type resulting in maximum system efficiency. The core design allows for control of multiple hot water boilers in any combination of size and type, and extends to control and optimize the use of condensing, non-condensing, and hybrid boiler systems. This allows management of a heating load as the control calculates independent PID loop for the condensing and non-condensing boilers, respectively. The control uses the monitored system variables to select and operate the appropriate boiler or boilers from operating groups or banks of boilers. This approach optimizes boiler and boiler system efficiency and equipment life The system incorporates thermal shock routines to protect the non-condensing boilers by pre-heating incoming water to keep the inlet to the non-condensing above the required minimum temperature.

- Master control for multiple IWT boilers

- Allows central control of all boilers

- Enables remote monitoring

- Modulates IWT boilers in unison

- 10” color touch-screen interface, PLC-based

- Unison control of multiple IWT boilers

- Auto-rotation schedules

- Run-time monitoring

- Built-in intelligence for system control

- User-friendly interface

The Cleaver-Brooks IWT Plant Master is the central interface between each boiler’s control system and other boiler room equipment to external remote monitoring or building automation systems. It controls the unison modulation of IWT steam boilers. The system includes auto-rotation control to maintain equal amount of run hours on each boiler in the system. Setup and control are easy with the HMI’s user-friendly menu system and setup screens.

Watertube Boilers

Optimal versatility in a highly efficient, compact unit.

- FLX

- FLX PM

- M5

- M5M

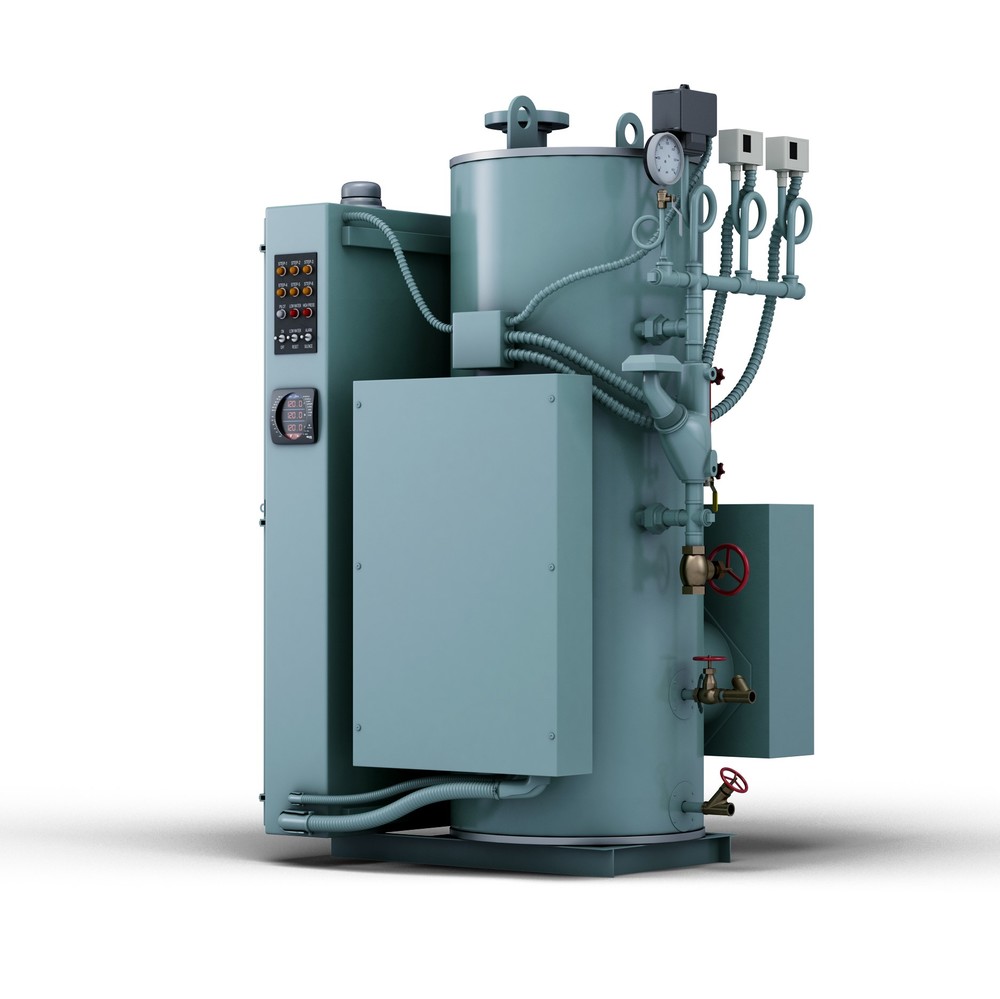

The Cleaver-Brooks Model S is an immersion-element steam electric boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Available in vessel sizes ranging from 12″ to 48″ diameter with an output spanning 12 kW to 2,250 kW. A typical Model S boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric vertical steam boiler

- 12 to 2250 KW – up to 7,875 lb/hr

- Up to 600V

- 15, 150, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation

The Cleaver-Brooks Model WB is an immersion-element hot water boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Vessel sizes range from 12″ to 42″ diameter with an output spanning 12 kW to 3,360 kW. A typical Model WB boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric hot water boiler

- 12 to 3360 kW, up to 11.5 million Btu/hr

- Up to 600V

- 160, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation with virtually no noise emissions

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation