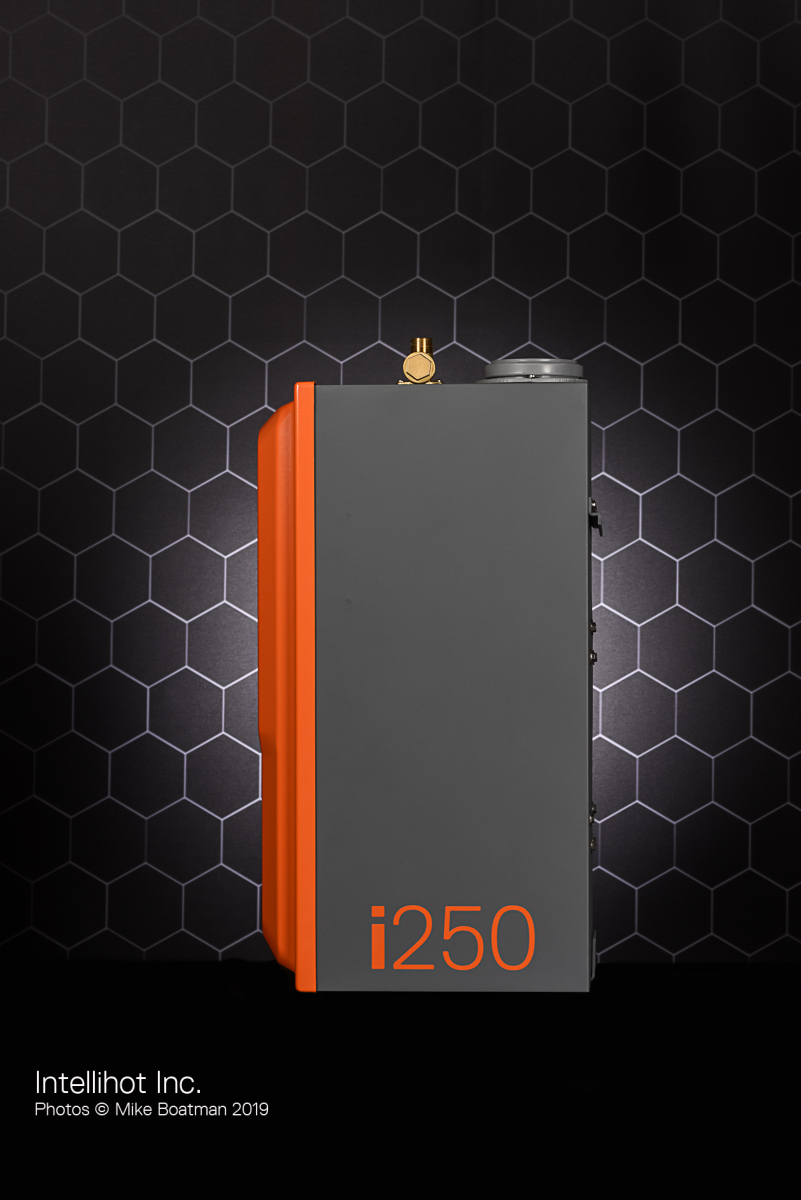

Count on superior performance and reliability from the i Series line, with the i200 and i250 tankless water heaters. Designed to be commercial “workhorses,” the i Series units are ideal for highly variable applications using potable hot water. Each is engineered with minimal components to maximize durability—even in the most demanding commercial applications.

Key Features:

- 200,000 to 250,000 Btu/h for light commercial applications

- Slashes capital cost up to 50%, reduces operational cost up to 30% (compared to traditional systems)

- 98% condensing combustion efficiency (energy factor = .93)

- Always operates at set point – never drops in temperature

- Operates on very low gas pressure down to 2.5″

- Takes up 80% less space than a typical tank water heater

- Industry’s best design, operation and efficiency when combined with storage

- Accommodates 3″ PVC exhaust venting up to 100 feet, or 2″ PVC up to 26 feet

- ASME option (iQ Series)

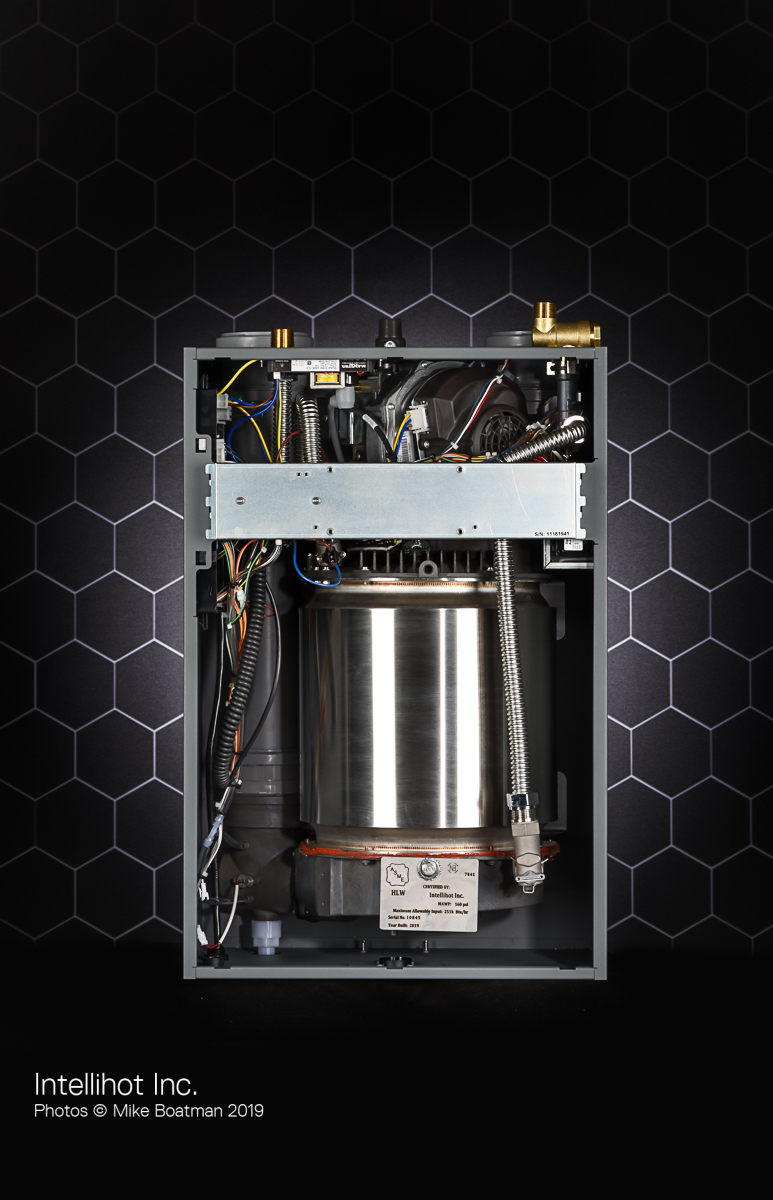

Intellihot has created a revolutionary heat exchanger after years of research that is the best in the industry. At the heart of the iQ Series heat engine is a single finned stainless coil designed to float freely. This unique feature allows for rapid thermal cycles by allowing the coil to expand or contract. Coldwater enters the coil at the bottom and is carefully heated to the correct temperature before emerging at the top, ready for use. The modulating premix burner fires radially outwards to precisely match the load. By condensing the flue gas, we’re able to absorb 12% more heat than in other models. The condensate flows downwards in the same direction as the flue gas, preventing any gas side fouling. Flue gasses move downwards to the bottom, casting while water flows in the opposite direction, collecting maximum heat along the way. Using a patented vibration and turbulent flow technology, the iQ Series heat exchangers possess the unique ability to be “self-descaling,” keeping limescale in suspension and ensuring years of like-new operation. These features and many others can be found in these intelligent water heaters – only from Intellihot.

These commercial hybrid water heaters can be cascaded for increased capacity. And yet, each one operates autonomously. This means cascaded units do not require a master controller (the kind that causes a single-point failure).

With Intellihot’s patented design, each iQ Series unit has enough internal intelligence to perform independently. In fact, if any one unit needs to be checked or serviced, the cascade will continue to function smoothly to ensure continuous hot water.

Intellihot provides six iQ Series models: iQ3001, which delivers 3 million BTUs, iQ2001, which delivers 2 million BTUs, iQ1501, which delivers 1.5 million BTUs, iQ1001, which delivers 1 million BTUs, iQ751, which delivers 751,000 BTUs, and iQ251, which delivers 251,000 BTUs.

The iN401 iN501 iN199 are the first drop-in ready tank replacement units that provide all the features and benefits that Intellihot is known for, in a smaller and more compact footprint.

Key Features:

- Compact Drop-In Replacement – Neuron Series units are over 8″ slimmer than a typical tank and feature similarly located water in and out for easy hook up without the need to re-pipe. Replace typical tank units in a flash.

- Built-In Redundancy – (iN401, iN501) Neuron Series models come with two separate heat engines, independently controlled thus eliminating additional expense and space for a redundant backup water heater.

- Direct Cell-LTE Connectivity – Remotely access and monitor Neuron Series units via LTE cell connectivity feature. No need to connect to your building’s Wi-Fi.

- Mobile App, telliCare® – Use Intellihot’s mobile app and start monitoring your unit. Check water inlet/outlet temperatures, flow rates, flue gas temperatures and life of key parts, available on your mobile device of choice.

- Low Gas Pressure Operation – System operates on low gas pressure, down to 2.5″ WC, without reduction of capacity.

- Mitigate Legionella Risk – With no storage tanks there’s less risk for Legionella growth. Eliminate the need for mixing valves and their associated unreliability and costs.

Intellihot’s heat exchanger floats freely to accommodate all thermal shocks and stresses. Made of 316L stainless steel it offers superior corrosion and erosion resistance. It has a patented, self-descaling design that prevents limescale buildup. It has no welds on the water side to ensure robustness to chlorides. These heat exchangers create energy reduction of up to 40%+ when compared to tank-type water heaters and 15%+ over other non-condensing water heaters.

Watertube Boilers

Optimal versatility in a highly efficient, compact unit.

- FLX

- FLX PM

- M5

- M5M

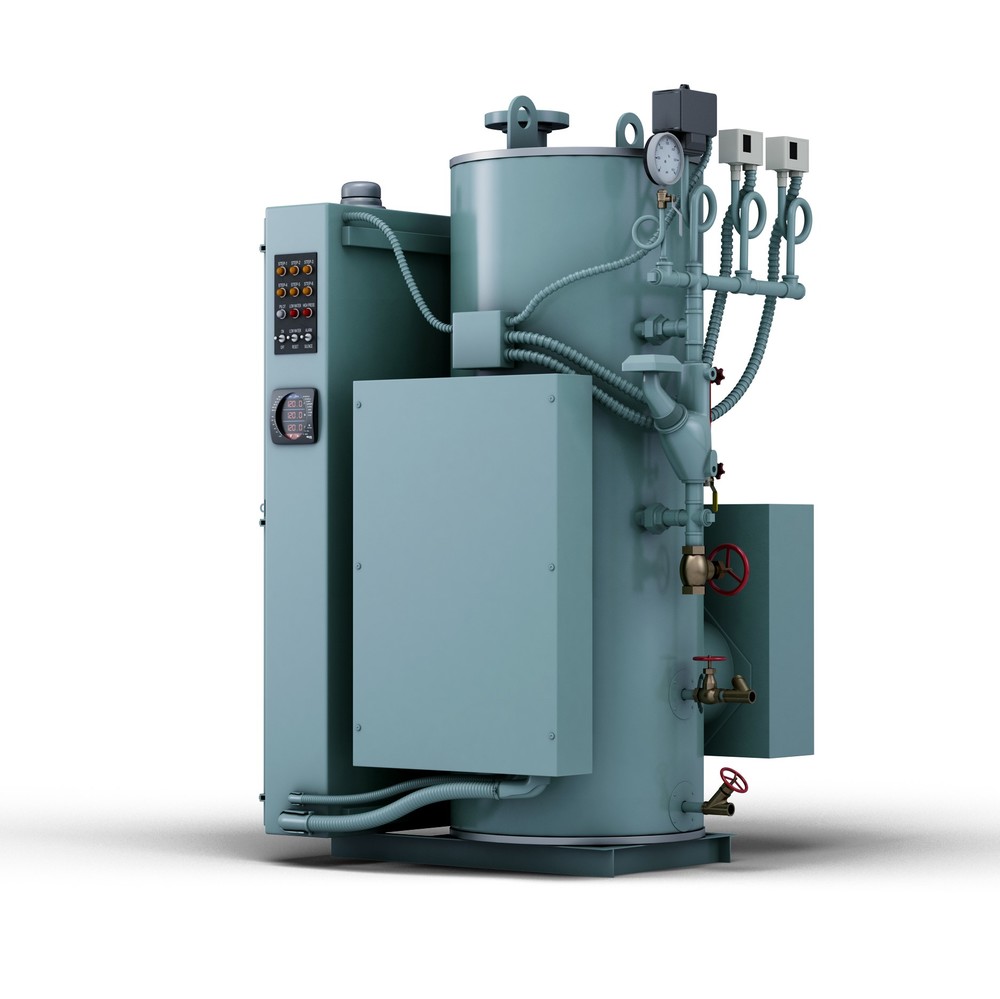

The Cleaver-Brooks Model S is an immersion-element steam electric boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Available in vessel sizes ranging from 12″ to 48″ diameter with an output spanning 12 kW to 2,250 kW. A typical Model S boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric vertical steam boiler

- 12 to 2250 KW – up to 7,875 lb/hr

- Up to 600V

- 15, 150, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation

The Cleaver-Brooks Model WB is an immersion-element hot water boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Vessel sizes range from 12″ to 42″ diameter with an output spanning 12 kW to 3,360 kW. A typical Model WB boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric hot water boiler

- 12 to 3360 kW, up to 11.5 million Btu/hr

- Up to 600V

- 160, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation with virtually no noise emissions

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation