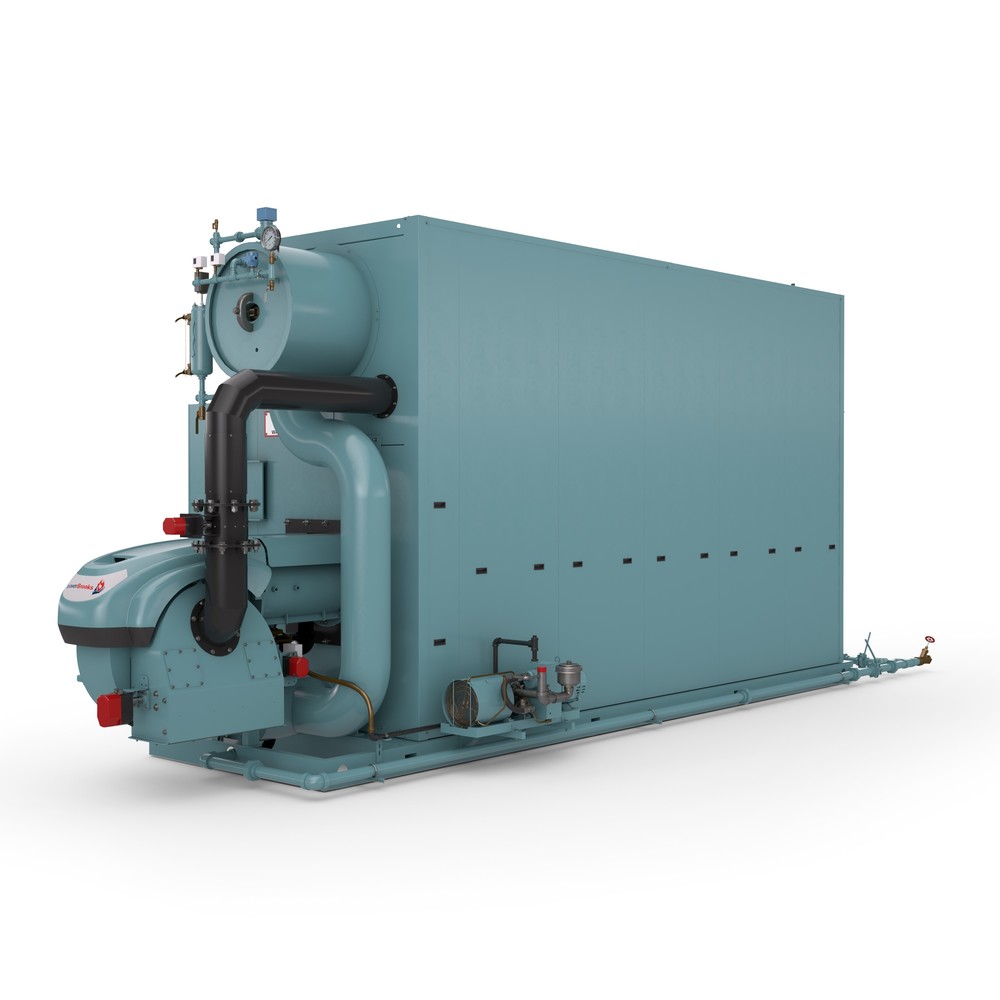

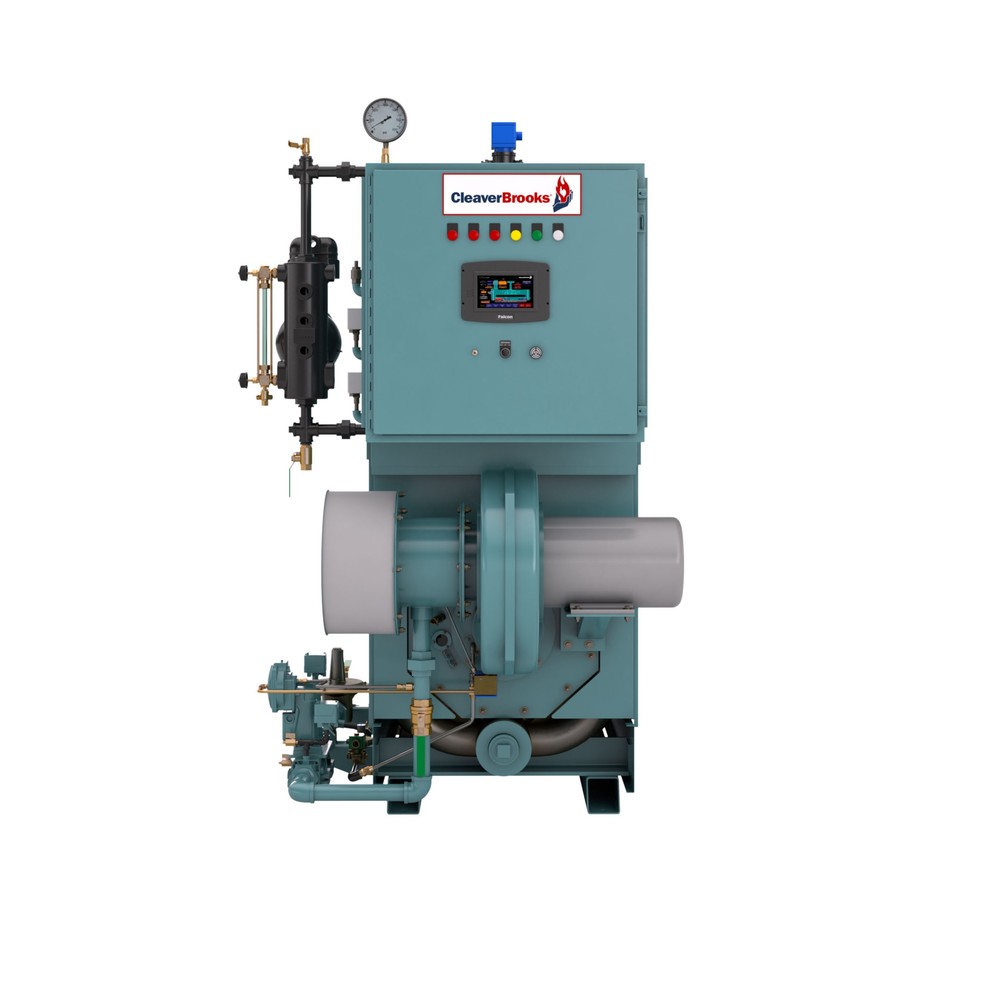

- Steam or Hot Water

- 1,500-25,000 MBH Input

- Natural Gas, #2 Light Oil, Propane, Digester Gas

- Available to <9 ppm NOx

- Field Erectable

- Up to 10:1 turndown (Uncontrolled emissions) and 5:1 (Controlled emissions)

- Small footprint

- Thermal shock resistance

- Hinge-mounted burner and removable panels allow easy access for service and maintenance

- 25-year limited pressure vessel warranty

v15-250 psig Design Pressure

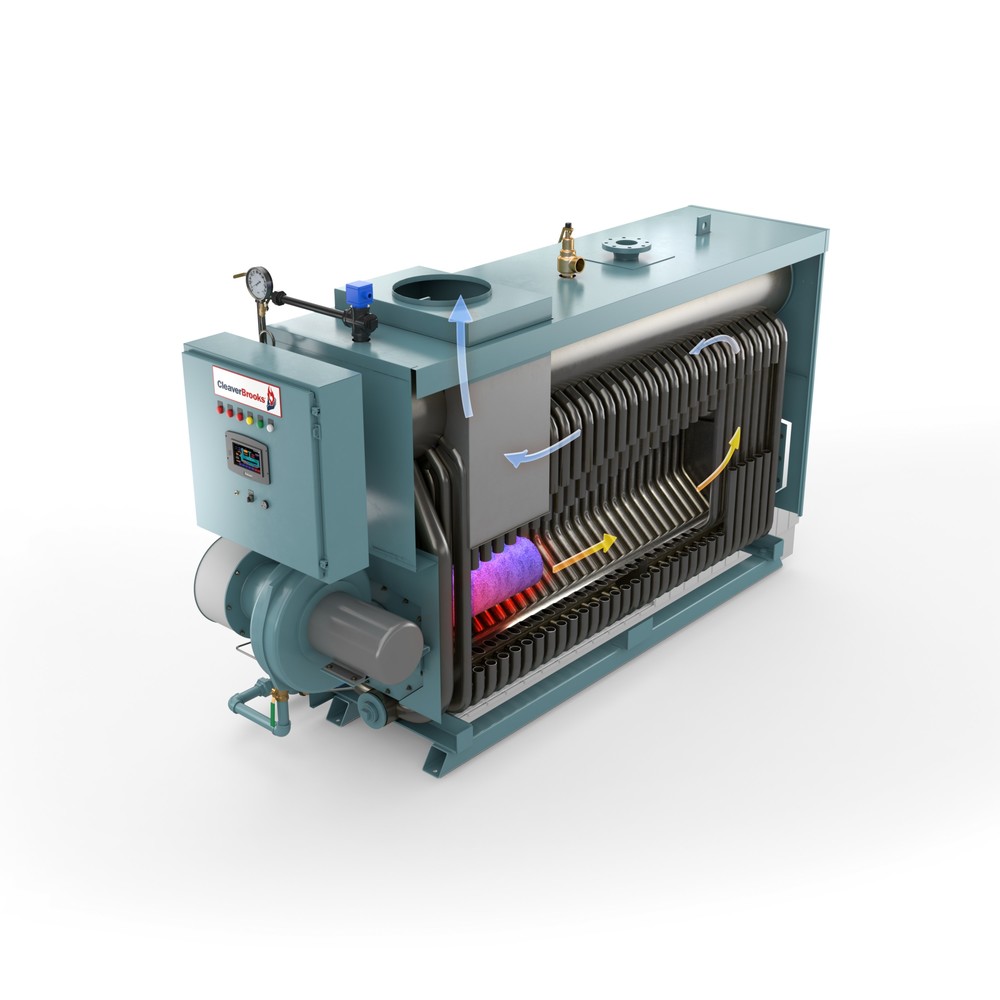

The Flextube can burn renewable fuels and features a fully modulating burner to ensure optimum efficiency throughout the firing range. It can also help meet emissions reduction goals, down to <9 ppm NOx with low CO. The FLX has distinct design features that include non-welded ferrule tubes for ease of tube replacement. The package includes a ProFire burner for a completely integrated and engineered solution from a single source. Removable sectioned side panel design permits full access to all tubes. The field erectable option allows you to replace boilers in tough to access spaces. The pressure vessel is assembled at the factory and hydro tested. During the disassembling the tubes are matched marked for easy installation on site. The boiler is a 5-pass cross flow water tube design. This allows for maximum heat transfer thru every pass. The gas flow design of the FLX does not require baffles which lowers maintenance costs throughout the boiler’s life. A fully water-cooled furnace reduces heat loss from the furnace section. The design eliminates the need for costly maintenance on side or rear insulation, which reduces the total cost of ownership.

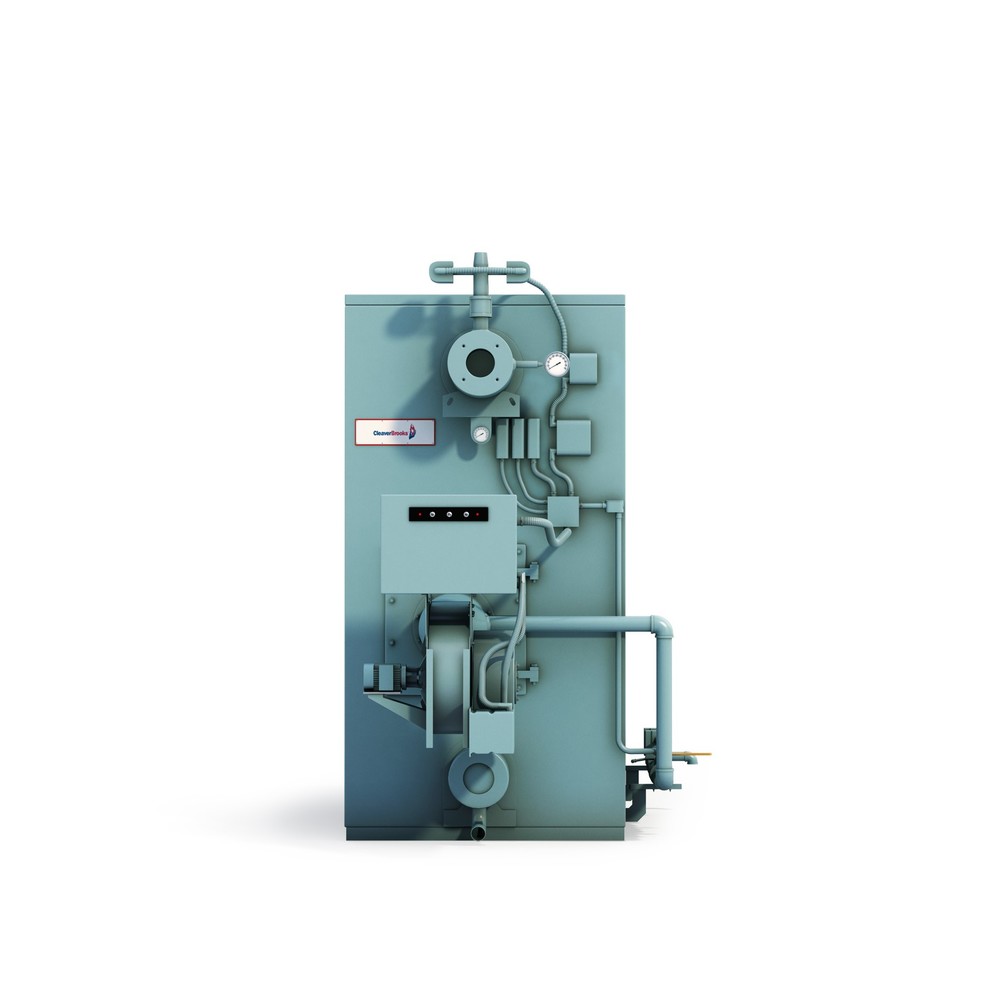

- Steam or Hot Water

- 75-250 HP (3,150-10,500 MBH Input)

- Natural Gas, Propane

- 15-250 psig Design Pressure

- Premix Burner Technology

- Standard sub-20 ppm NOx, Optional sub-9 ppm NOx

- Field Erectable

- Up to 5:1 turndown

- Small footprint

- Thermal shock resistance

- Hinge-mounted burner and removable panels allow easy access for service and maintenance

- 25-year limited pressure vessel warranty

The FLX Premix (FLX PM) boiler achieves best-in-class combustion performance with low emissions. Premix burner technology enables the boiler to attain <20 ppm NOx without FGR and <10 CO as standard on natural gas. The modulating burner control automatically adjusts the air/gas mixture for maximum efficiency and optimum turndown. The FLX PM integrates a servo-driven, fuel-input control valve with air-input control via a variable-frequency-driven fan for precise fuel/air ratio control. The field erectable option allows you to replace boilers in tough to access spaces. The pressure vessel is assembled at the factory and hydro tested. During the disassembling the tubes are matched marked for easy installation on site. The boiler is a 5-pass cross flow water tube design. This allows for maximum heat transfer thru every pass. The gas flow design of the FLX PM does not require baffles which lowers maintenance costs throughout the boiler’s life. A fully water-cooled furnace reduces heat loss from the furnace section. The design eliminates the need for costly maintenance on side or rear insulation, which reduces the total cost of ownership.

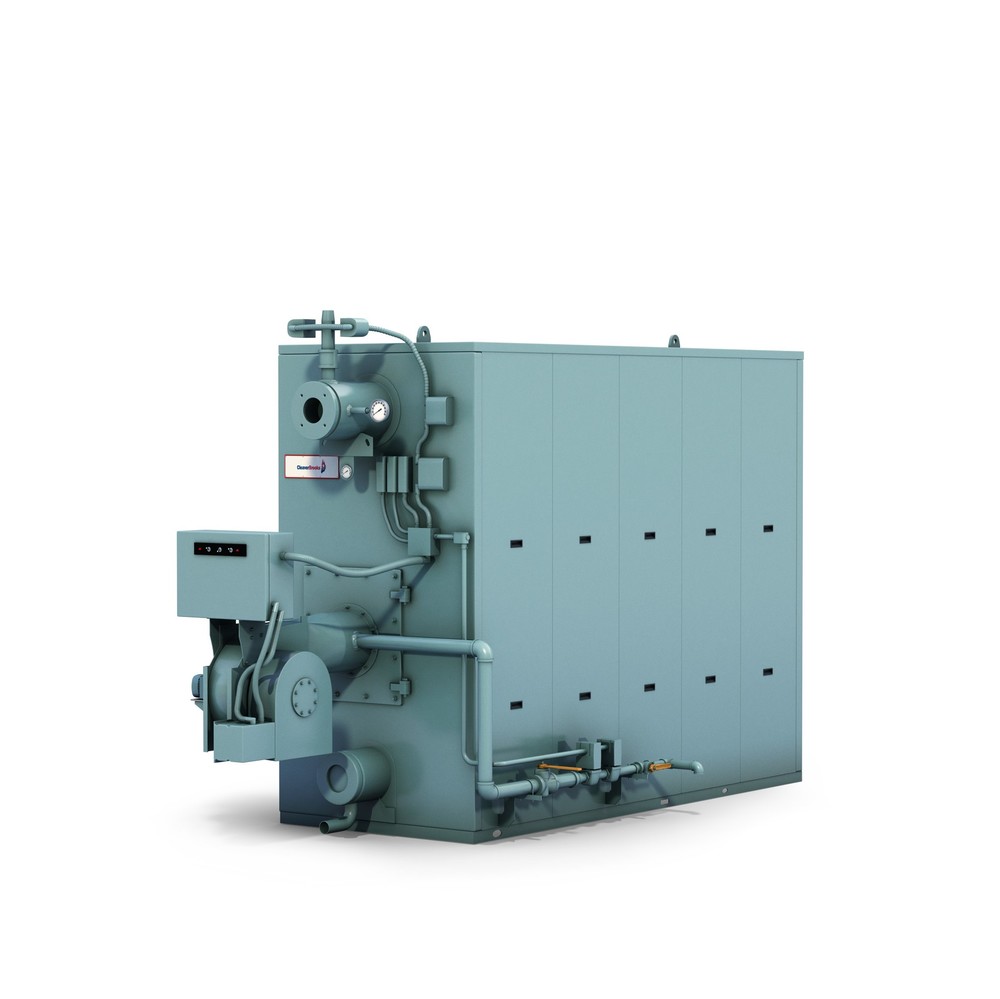

- Steam or Hot Water

- 1,500-8,000 MBH Input

- Natural gas, #2 Light Oil, Propane

- 15-500 psig Design Pressure

- Integral burner for maximum efficiency)

- Ease of installation

- Quiet: <70 dBA sound level

- Low water volume designs

The Model 5 membrane wall watertube boiler is a high-performance, super-compact unit designed specifically to fit through a doorway. The integral burner design is proven CB technology that is robust and can be setup for dual fuel applications. The hinged wind box allows easy access for service and maintenance. The Model 5 is a compact unit that reduces floor space by 50% with weight savings of 40% while providing steam or hot water for commercial or industrial applications. The complete package fits through a standard doorway, ideal for replacement of existing units with ease of installation and minimal cost. The Soot washer lances in the upper convection area of the boiler allow ease of maintenance when firing on #2 oil. Each lance is capable of rotating 360 degrees to ensure complete washing of the convection zone.

Watertube Boilers

Optimal versatility in a highly efficient, compact unit.

- FLX

- FLX PM

- M5

- M5M

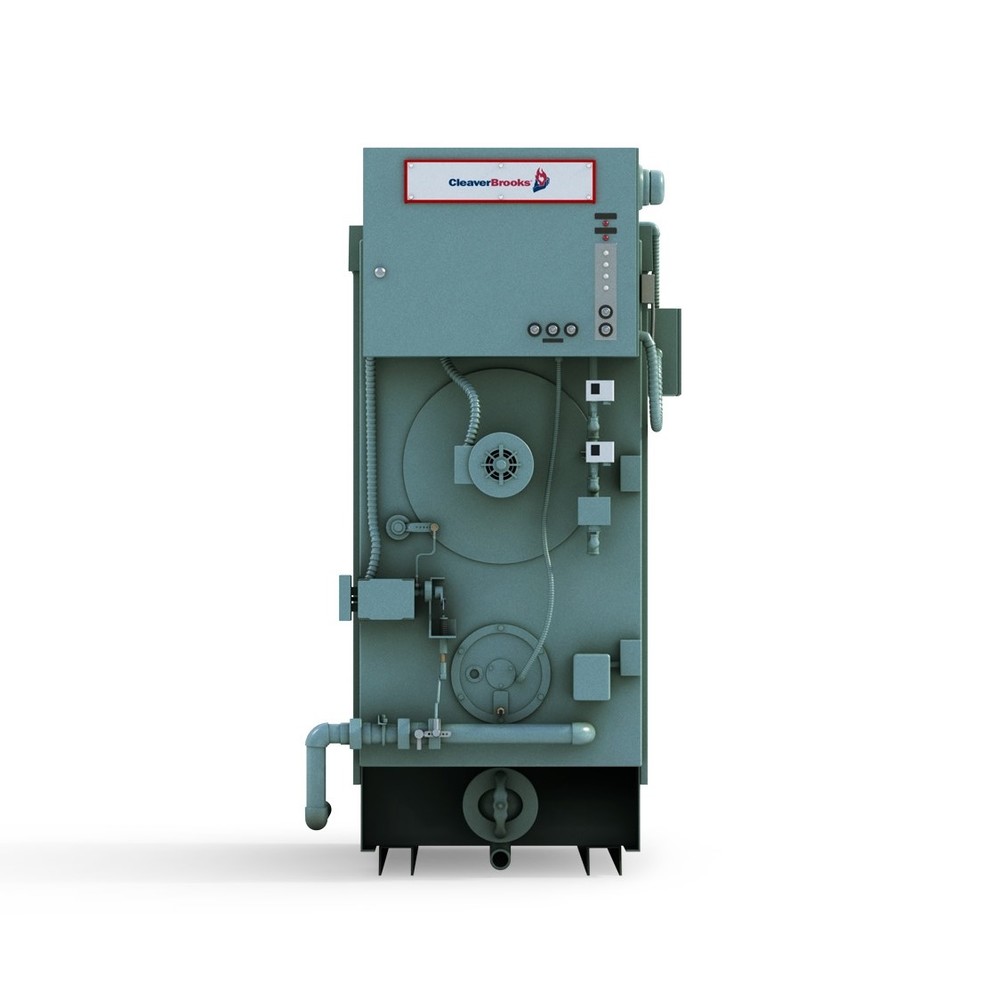

- Steam or Hot Water

- 2,000-6,000 MBH Input

- Natural Gas, Propane

- 15-500 psig Design Pressure

- Premix Burner Technology

- Standard sub-20 ppm NOx

- Up to 5:1 turndown

- Linkageless control automatically adjusts the air/gas mixture

- Maintains peak operating efficiency during low system demand

- Increases boiler room floor space by 50%

- Ease of installation

The M5M is a membrane wall watertube boiler that achieves best-in-class combustion performance with low emissions that can fit through a doorway. Premix burner technology enables the boiler to attain <20 ppm NOx without FGR and <10 CO as standard on natural gas. The linkageless burner provides fully modulating turndown without the use of complex air/fuel mixing valves. Premix burner technology enables the boiler to attain <20 ppm NOx without FGR and <10 CO as standard on natural gas. The linkageless burner provides fully modulating turndown without the use of complex air/fuel mixing valves. The M5M is a compact unit that reduces floor space by 50% with weight savings of 40% while providing steam or hot water for commercial or industrial applications. The complete package fits through a standard doorway, ideal for replacement of existing units with ease of installation and minimal cost.

The Cleaver-Brooks Model WB is an immersion-element hot water boiler with a vertical, insulated vessel. This boiler is designed for the heavy-duty, continuous demand of commercial and industrial applications. Vessel sizes range from 12″ to 42″ diameter with an output spanning 12 kW to 3,360 kW. A typical Model WB boiler system includes operating controls, elements, fuses, contactors, safety valve, and instrumentation.

- Electric hot water boiler

- 12 to 3360 kW, up to 11.5 million Btu/hr

- Up to 600V

- 160, 200 & 250 psig

- No site emissions

- Compact design and smaller footprint

- No site emissions

- Quiet operation with virtually no noise emissions

- Nearly 100% efficiency at all operating points

- Ease of maintenance with reduced complexity/number of moving parts

- All units are fully packaged and ready for installation