With Burners & Controls under the microscope, this weeks post features Cleaver-Brooks’ industrial burners proudly sold and serviced by Cannepp, your expert boiler and service provider. Click the links in bold for product descriptions, and check out the gallery at the bottom for specifications and additional info!

NATCOM Utility Burner

Experience and expertise are the two most outstanding qualities that this product has honed across years of development, now capable of finding “solutions for new emissions requirements, fuel conversions, and retrofit upgrades in industrial, utility, and power boiler facilities.”

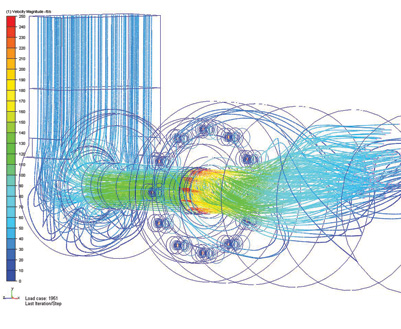

“By optimizing the combustion air distribution and fuel mixing dynamics using proprietary CFD software, NATCOM-patented HyperMix™ technology can minimize NOx, CO, and PM emissions on new or retrofit projects meeting the most demanding air permit requirements.” – CBm

Cleaver-Brooks’ noted features of this product include “ultra-low-NOx, CO, volatile organic compounds (VOC) and PM emissions, a reliable air shutter and oil atomizer retraction mechanisms, a stable and dependable ignition systems, and a low maintenance design.”

NATCOM Specialty Burner Systems

This unit is built to achieve the highest possible performance for thermal process operations while also producing the lowest overall emissions. Top-notch engineering, system modeling and testing make it ideal for industrial drying, air-heating or thermal oxidation. Benefits of this specialty solution include “lower NOx emissions, lower excess air, improved efficiency, reduced equipment footprint, and greater flexibility that make it future-proof.”

NATCOM NXT

For new boilers and retrofit markets, these models use advanced CFD modeling and possess advanced features like “adjustable gas injectors, Class-III igniters, atomizers with coupling block valves, industrial-grade pneumatic actuators, and 4-20mA positioners.” The NXT line also uses heavy-duty fan construction that increases equipment longevity and assists in noise reduction. A windbox-mounted control panel and fuel train meet ASME requirements and alleviate shipping headaches. Key features include a large capacity, and air-handling equipment package, and a control system with a fully-metered CCS.

NATCOM Fuel Train

Covering burners in relation to the combustion process makes it important to look at fuel trains as well. NATCOM offers assembled systems for gas and liquid fuel applications. The product reliably delivers when it comes to moisture removal management and pressure reduction, and also possesses a gaseous fuel mixing station and knockout tanks, all while meeting a vast array of safety standards and addressing hazardous location concerns.

NATCOM Duct Burner

This model designed for steam applications promises the “lowest levels of NOx, CO, VOC, and PM emissions available, even in the most challenging service conditions.” Moreover, Cleaver-Brooks positions this unit as “the only duct burner supplier to offer a complete system with an innovative duct burner solution for the co-generation and combined cycle markets.” Their in-house simulation of the unit in relation to the future installation allows for “accurate modelling of the turbine exhaust flow, distribution grid, combustion, heat recovery system and selective catalytic reduction performance.”

ProFire-XL Series

This model is designed for large firetube and watertube applications in a vertical or horizontal configuration, featuring “a unique and precise air-metering system which permits accurate air-to-fuel settings for maximum combustion efficiency.” Additionally, the ultra-low NOx NT editions offer steam atomization in both configurations. The gas manifold on oil burners leaves room for future versatility-based upgrades to combo units. 10:1 and 8:10 turndown for gas and oil, respectively, and standard parallel positioning allows for “optimum control throughout the entire firing range.”

ProFire-D Series

The forced-draft design of this burner translates to hassle-free operation and high efficiency for numerous applications, while the backward-curved impeller allows for excellent performance at different furnace temperatures and altitudes. Full modulation and hinged combustion head for easy access makes for a painless operation throughout the burner’s life-cycle.

ProFire-S1 Series

What makes this model compelling is its versatility in relation to fuel options: “The standard S1 series offers natural gas, propane gas, air-atomized #2 or #6 oil and combination gas/oil fuel options from 46.2 to 63.0 MMBTU.” Hinged rear doors and access panels make for increased ease of access for maintenance purposes. Safety is also prioritized – an flue gas recirculation control valve and shutoff valve ensure accurate readings for NOx reduction, and prevent combustible gases from reentering the combustion chamber. Optional air atomizing low-pressure nozzles are also available for this model.

ProFire-E Series

The low pressure drop firing head design and low blower horsepower requirement lead to increased efficiency for this Cleaver-Brooks unit. Technological advances allow low NOx emissions options with a 10:1 turndown on natural gas and 8:1 turndown ratios on oil and low NOx gas. Efficiency meets reliability, as the E Series is also No. 2 oil capable for use as a backup fuel.

Check back with us next week when we look into control systems!